Tel: 0086-771-6306699

Fax: 0086-771-6306688

Website: www.zmjx6688.net

Website:en.zmjx6688.com

E-mail: gxzmjx2008@aliyun.com

Add: No. 19, Yongxing Road, Guangxi-ASEAN Economic & Technological Development Zone

Liquid loading coefficient≥70%

Stirring system

Top mechanical stirring system, aseptic mechanical seal system, DC stirring motor AC motor; Standard configuration 2-layer flat vane, first-class high-efficiency defoaming vane, bending vane axial flow vane are optional;

Speed control available, digital setting of rotation speed control.

Tank configuration

Stainless steel SUS316/SUS304;

Jacket temperature control, optimized diversion design;

Interior surface polishing, Ra 0.6μm; exterior surface polishing matte treatment;

Wide visual angle long-bar sight glass, PH electrode ,DO electrode, temperature electrode with complete connections;

The tank cover is equipped with the flame inoculation port standby feeding port.

Structure mode

Floor type framework, space saving, convenient operation.

Nominal volume

10L、15L、30L、50L、70L、100L、150L、200L……

Dosing system

Structure

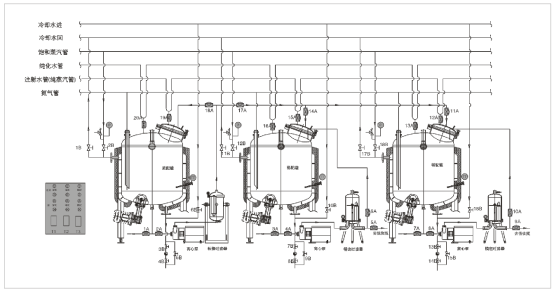

System composition

Liquid mixing system is mainly composed of transmission device, mechanical seal device, temperature control device, shoot the light, sight glasses, stirring device, manhole inlet, steam inlet, condensate water outlet, material outlet, drain outlet, sample connection, 360 °cleaning ball, some of them has orifice plate filter device, weighing metering device, liquid level measuring device, loop device, etc.

Application

Mainly used for biological engineering, infusion solutions, oral solutions, fine chemical industry material preparation

Used in sterile pharmaceutical preparations, biological agents, vaccines, such as eye drops drug manufacturing.

Through technical cooperation with internationally advanced enterprises, Zhongmeng carries out comprehensive technical promotion by adopting three-dimensional design concepts. Through our products services, we create higher market value for your products. We provide customers with solutions to high-end dispensing systems of sterile bulk drugs, lyophilized preparations, biological vaccines, blood products, injection preparations, large infusion, eyedrop, fat emulsion, etc.

Technical strength

●Fluid project examples over the ten years, professional manufacturing team, mature manufacturing process.

●Obtaining pressure vessel design .manufacturing qualification certificates of China's special equipment industry.

●The products have passed the inspection by FDA's inspection center, are awarded certificates.

●Nationally famous experts act as technical consultants of our company.

Automatic dispensing design

●Twice design of dispensing system cleaning optimization.

●Three-dimensional dynamic technology dynamic verification.

●Automatic SIP (dead-corner-free design).

●Tailing disposal non-residue design.

Online cleaning sterilization

●100% dead-corner-free cleaning design, one two fixed spray devices are installed at the top of the tank according to technological requirements.

●Online detection (conductance PH meter/TOC automatic detection).

●Online F0 value computation, synchronous curve display.